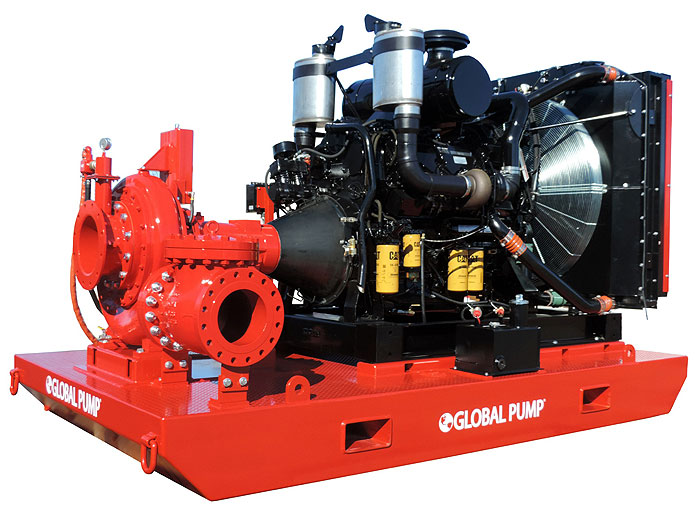

Global Pump pumps – for dewatering, sewage bypass, for high flow and high head applications

Global Pump is the US located manufacturer of high efficient trash pumps, and high head pumps.

The pumps available in sizes from 4 inch to 24 inch., capacities up to 3700m3/h

Global Pump units – general info

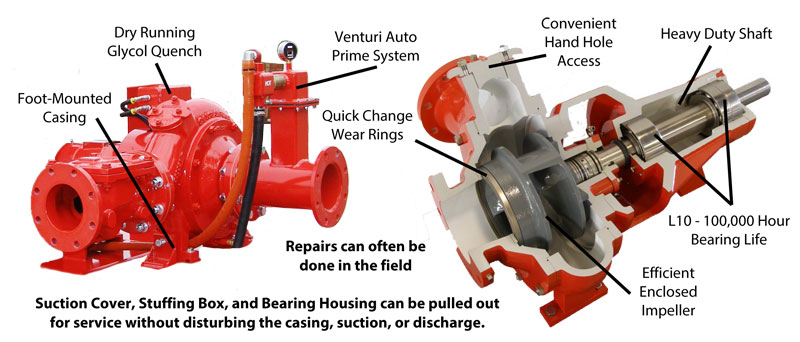

Global Pump GST, GHT, GSH, GHH series are based on pump sections with high efficiency enclosed impellers, with the ability to pump heavily contaminated liquids and wastewater.

Pump sections with high hydraulic efficiency (over 80%) allow for significant fuel savings, making the Global Pumps the most cost effective and competitive operating equipment.

Automatic priming, based on the venturi injector system with integrated compressor, allows for maximum vacuum up to 8.5m. Versions with the “venturi” system have a symbol ending in “AP” eg GSTAP, GHTAP, etc., and this is a standard recommended type of vacuum assist. On request, other variants of the vacuum system (eg diaphragm or oil pump) are available, but the injector system is perceived by many pump users as the most reliable compared to alternative solutions.

Global Pump units are available in the range of connection sizes from 100mm to 600mm, with flow rates from 90 to over 3600 m3 / h. (1500-60,000 lps.) And lifting heights (head) up to 185 m, solids handling depending on model are available up to 125mm.

Standard versions are driven by diesel engine. There are also available electrically driven and version in soundproof canopies.

*

Solutions used in Global Pump pumps

- Highest fuel consumption efficiency (high efficiency, over 80% in most models, makes them the market leader on this issue)

- Mechanical seal in glycol allows for dry running

- Large free impeller solids passage (eg 100mm in 8 inch pump)

- Low friction looses return valve design

- Ease of use and maintenance

- Durable and heavy duty construction

- As standard, ready for automatic work controlled by float switches

Global Pump – series and models of pumps

- GSTAP series – trash pumps , medium head (up to 50m) – więcej informacji

- GHTAP series – high head trash pumps, (up to 73m) – więcej info/rmacji

- GSHAP – standard high head pumps (up to 120m) – więcej informacji

- GHHAP – high performance high head pumps (up to 185m) – więcej informacji

Special material executions

Stainless steel CD4MCu version for demanding applications with increased corrosivity and abrasion

J

J

As an option, Global Pump offers a full line of its CD4MC-based pumps – a high grade duplex stainless steel dedicated for applications with high corrosivity and abrasion / abrasion.

CD4MCu is a Fe-Cr-Ni-Cu-Mo alloy with a duplex ferrite and austenite structure. Quite high strength and hardness combined with good ductility results in a high abrasion resistance and corrosion resistance.

The CD4MCu provides significantly better impact and corrosion resistance and less pitting than standard stainless steel. The material has a higher durability and therefore is more durable.

The selection of components for the pump should take into account many factors – including type of pumped liquid, PH, expected operating point parameters (efficiency, lifting height), pump speed, operating nature (continuous or not). Please contact us to find the best solution for your application.

CD4MCu pump versions – download PDF  (english)

(english)

Read also:

Trash pumps GSTAP, GHTAP series

Trash Auto Prime – GSTAP, GHTAP series – wide capacity range pumps with pompy wysokiej wydajności i podwyższonego podnoszenia do szlamów, ścieków, wody zanieczyszczonej

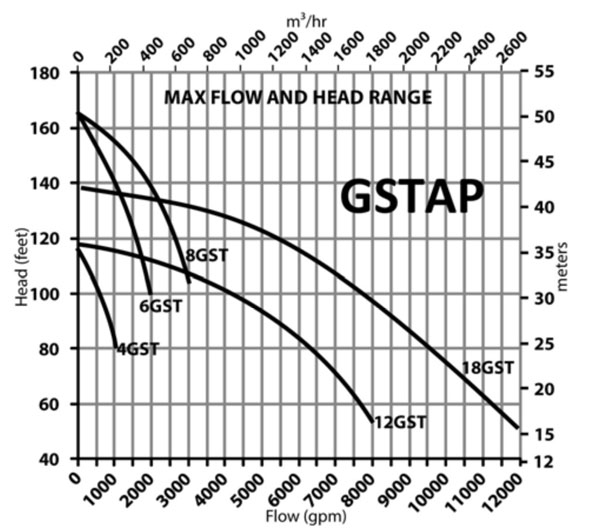

Seria GSTAP – trash medium head pumps

Standard Trash Auto Prime

GSTAP series is the universal series of multipurpose pumping units for heavily contaminated liquids, slurries, wastewater (solids handling up to 100mm) with medium heads of up to 35-50m. depending on the model.

| Model | Ports (mm) | Capacity max. | Head max | Example duty point | Solids handling |

| 4GSTAP | 100 x 100 | 284 m3/h. | 35 m | Q=180 m3/h. at H=27m |

75 mm |

| 6GSTAP | 150 x 150 | 625 m3/h. | 50 m | Q=300 m3/h. at H=36m |

75 mm |

| 8GSTAP | 200 x 200 | 772 m3/h. | 50 m | Q=500 m3/h. at H=38m |

100 mm |

| 12GSTAP | 300 x 300 | 1885 m3/h. | 36 m | Q=1200 m3/h. at H=27m |

100 mm |

| 18GSTAP | 450 x 350 | 2840 m3/h. | 42 m | Q=1800 m3/h. at H=32m |

100 mm |

GSTAP pumps – performance curves

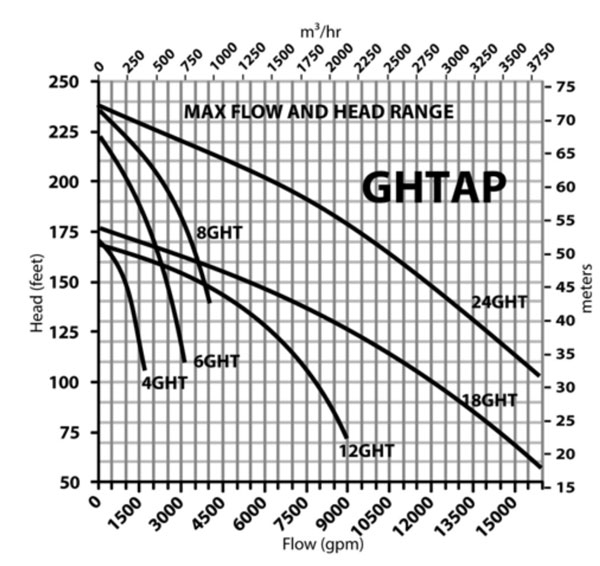

GHTAP series – trash pumps with higher head – High Trash Auto Prime

GHTAP series are suitable for pumping heavily contaminated liquids and wastewater (solids handling up to 125mm) with the possibility of obtaining higher head/pressure in the range of up to 51-73m depending on the model.

GHTAP pumps will work well both for long distance pumping and can be useful in open pit mines as well as for pumping liquids with higher specific gravity.

| Model | Ports(mm) | Capacity max. | Head max. | Example duty point | Solids handling |

| 4GHTAP | 100 x 100 | 365 m3/h. | 53 m | Q=200 m3/h. at H=43m |

75 mm |

| 6GHTAP | 150 x 150 | 727 m3/h. | 67 m | Q=450 m3/h. at H=50m |

75 mm |

| 8GHTAP | 200 x 200 | 1000 m3/h. | 70 m | Q=600 m3/h. at H=58m |

100 mm |

| 12GHTAP | 300 x 300 | 2000 m3/h. | 51 m | Q=1200 m3/h. at H=33m |

100 mm |

| 18GHTAP | 450 x 350 | 3400 m3/h. | 54 m | Q=2000 m3/h. at H=40m |

100 mm |

| 24GHTAP | 600 x 600 | 3634 m3/h. | 73 m | Q=2500 m3/h. at H=50m |

125 mm |

GHTAP pumps – performance curves

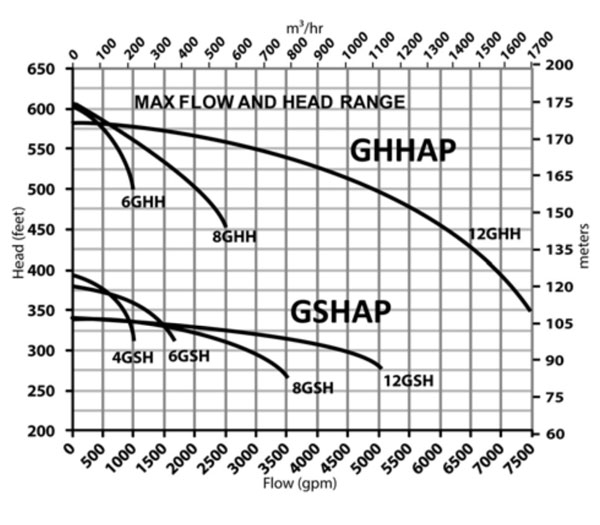

High head pumps Global GSHAP, GHHAP

Series GSHAP – standard high head pumps

Standard High Head Auto Prime

GSHAP and GHHAP pumps are high and very high head pumps (up to 185m) .

GSHAP – models

| Model | Ports (mm) | Capacity max. | Head max. | Example duty point | Solids handling |

| 4GSHAP | 100 x 75 | 250 m3/h. | 120 m | Q=200 m3/h. at H=100m |

15 mm |

| 6 GSHAP | 150 x 100 | 450 m3/h. | 110 m | Q=325 m3/h. at H=100m |

22 mm |

| 8GSHAP | 200 x 150 | 800 m3/h. | 105 m | Q=550 m3/h. at H=95m |

34 mm |

| 12GSHAP | 300 x 200 | 1000 m3/h. | 100 m | Q=900 m3/h. at H=95m |

38 mm |

Series GHHAP – high performance high head pumps

Hyper High Head Auto Prime

GHHAP – models

| Model | Ports (mm) | Capacity max. | Head max. | Example duty point | Solids handling |

| 6GHHAP | 125 x 100 | 284 m3/h. | 185 m | Q=200 m3/h. at H=160m |

22 mm |

| 8GHHAP | 200 x 150 | 625 m3/h. | 185 m | Q=400 m3/h. at H=160m |

34 mm |

| 12GHHAP | 300 x 200 | 772 m3/h. | 180 m | Q=1000 m3/h. at H=165m |

63mm |

GSHAP, GHHAP – performance curves